Contents

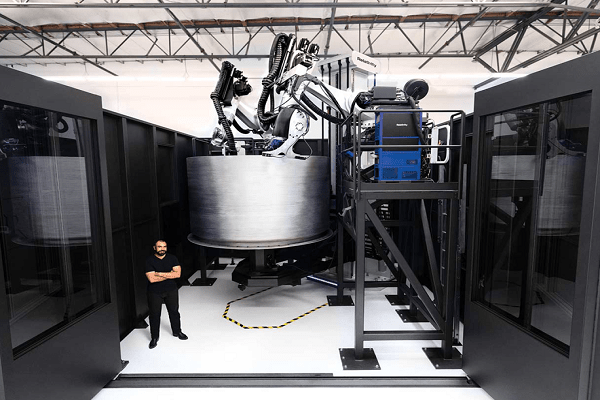

The last decade has seen a lot of revolutionary developments in the world of 3D printing. 3D printing has gone from strength to strength and now seems to be poised to take the industry by storm. If you wonder about the significant developments in High Strength 3D Printing Service, then look no further than the High definition revolution. 3D technology is getting better every day and is set to change the way industries think about high-definition imaging.

Developments in 3D Printing Technology

The recent rapid growth in 3D printing technologies has brought many exciting developments to the table for both designers and users. Despite CO VID-19 being passed, the technology still thrived, and some fascinating new developments took place. These include solid vinyl printers, resin 3D printers, metal 3D printers, and solid rubber 3D printers. Solid vinyl printers are one of the most advanced 3D printing technologies currently available due to their ability to print with significant volumes in a short period. Resin 3D printers have made huge strides forward, offering high-quality prints from durable materials such as ABS.

This is a relatively simple question but probably the most frequently asked question by an enthusiast. The answer to this question will help you decide what type of machine will suit your needs best. The newer generation printers use an improved version of laser technology and new polymers that offer more resistance to wear. They also allow users to produce a much higher quality print with fewer layers, a feature that was first introduced with the inception of the compact 3D printer.

Strength of a Print

The strength of your prints depends heavily on the quality of your surface. This is because the surface must be able to withstand the extreme heat that is created during the printing process. To meet this challenge, resin 3D printers manufacture surfaces that consist of many tiny bubbles or grains of plastic. These grains are fused using a chemical that hardens when heated, and this bonding process provides strength similar to that of metals. To achieve this level of durability, the grains must be coated with a high-temperature polymer solution, which is responsible for the additional strength. As well as providing additional strength, these coatings also contribute to the overall color accuracy of the final object.

Also read: Print a Test Page Online

Manufacturing Methods

This type of technology is already being used in traditional manufacturing methods such as woodworking and metalworking. It can also be applied in several non-traditional manufacturing methods, such as fashion design and sculpture. It can also be used in interior design, special effects, photography, film development, and computer-aided design, among oD printing, offers several unique advantages over traditional manufacturing methods.

In the case of automobiles, composite 3D printing has already been used in several instances to improve the quality of the final object. For example, in the case of cars, manufacturers have been able to make small changes to certain car parts without replacing the whole object. By combining different types of plastic materials, composite 3D printing has enabled car manufacturers to improve the visibility of the vehicle’s body, thus making it more visible at night and increasing the vehicle’s safety. In addition, composite 3D printing has enabled manufacturers to create various finishes, from gloss, flat, matte, or glossy, for a wide variety of different types of models and makes of automobiles. This means that one manufacturer’s product can be adapted to fit the needs of several different types of cars.

Use of Digital Light

In addition to this, another exciting development in 3D printing is the use of digital light synthesis. This is a form of digital printing that several large corporations have adopted to print out parts that have either been designed or prototype pieces. The benefit of using digital light synthesis as a printing method is that it produces parts that have consistent mechanical properties. This means that when the final product is produced, it will have precisely the same mechanical properties as the model or prototype that was printed out. By printing with digital light synthesis, many companies have been able to reduce the cost of production.

Conclusion;

In addition to this, it is also now possible to create complex designs with the help of the best in modern technology – the invention of the solid-state laser printer. This is one example of significant development in 3D printing, in which two laser beams are used to generate a solid structure. Once this is created, it is then passed through several successive layers of resin to give it the three-dimensional effect to ensure that the product can be mass-produced. The introduction of these new technologies has helped improve the quality of the parts that we use day in and day out, allowing them to offer greater longevity and durability than ever before.