Contents

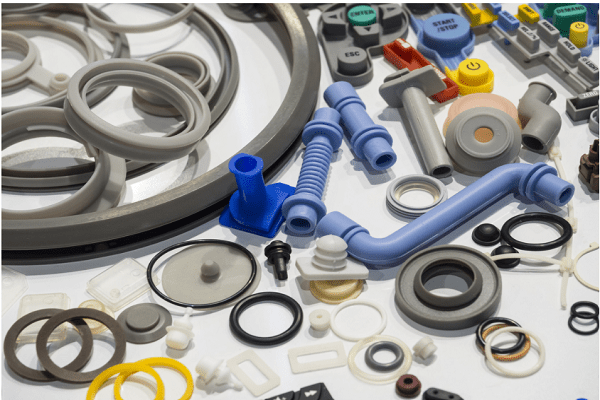

Rubber is a versatile and flexible material that can be used in a range of applications. Since natural rubber was first discovered in 1600 BCE, it has become a material we rely on. While natural rubber is still widely used, there is also a synthetic alternative.

Rubber is unique because, with a few modifications, it can be adapted to suit different industries. From automotive to medicine, it is often a critical component for preventing leaks and maintaining safety.

In the following article, we’ll share just a few applications that rubber can be used in.

Automotive and Aircraft

Viton Fluorocarbon is a synthetic rubber that contains a mix of fluorine and carbon. Fluorocarbon seals are commonly used in aircraft and automotive applications.

What are the features of fluorocarbon? It is resistant to high temperatures and chemicals, and is commonly used for seals and o-rings. The standard compound can withstand temperatures between -13° and +446°F, while the special compound can withstand -40° to +446°F. While fluorocarbon works well in high-heat ranges, it is not recommended for persistently low temperatures.

Whether it’s an automotive fuel handling system or a seal for an aircraft engine, this type of rubber will get the job done.

Health and Medicine

Medical seals need to meet industry regulations and be made from medical-grade materials. These rubber elastomers come with high-chemical and heat resistance, and low gas permeability.

Liquid silicone rubber, Viton fluoroelastomer and ethylene propylene are three commonly used rubbers for medical use. Temperature ranges vary, and the option used will vary depending on the product. For example, liquid silicone rubber can withstand low temperatures down to -85°, while fluoroelastomers are better in high temperatures, up to +446°F.

In medicine, rubber can be found in different items including seals and o-rings, pumps, implants, ventilators, IVs and feeding devices. Seals and components can be custom made, they can even be supplied for micro-sized applications.

Food and Drinks

Materials that come in contact with food need to be deemed safe by the FDA (Food and Drug Administration). Some rubber variants are ideal, as they have been tested for food safety. The most popular options include fluorocarbon, neoprene, silicone, ethylene propylene and nitrile.

There are a few key features the FDA looks for when deciding which materials are food safe. For example, they should be non-toxic, non-allergenic and reliable in different conditions and temperatures. They should be odorless, tasteless and resistant to bacteria.

When it comes to food applications, food-grade silicone seals stand out. This type of rubber is heat and chemical resistant and has low toxicity. It will withstand temperatures between -148°F to 600°F and is durable and long-lasting. And, it’s dishwasher, microwave and freezer safe.

You might find silicone in seals and o-rings, cookware, refrigerators and drink bottles.

Also read: How startups help in creating job opportunities for youth in India

Rubber Is a Unique Choice

Rubber may not be something you have thought about, but it is a material that is used in a range of applications. Many industries rely on rubber, as it is modified to suit different temperatures and conditions.

Rubber is commonly used for seals, with fluorocarbon the material of choice in vehicles. Medical devices use medical-grade rubber for o-rings, ventilators and pumps. And, among other materials, food-grade silicone has been approved by the FDA and is a common feature in products that come into contact with food.