Contents

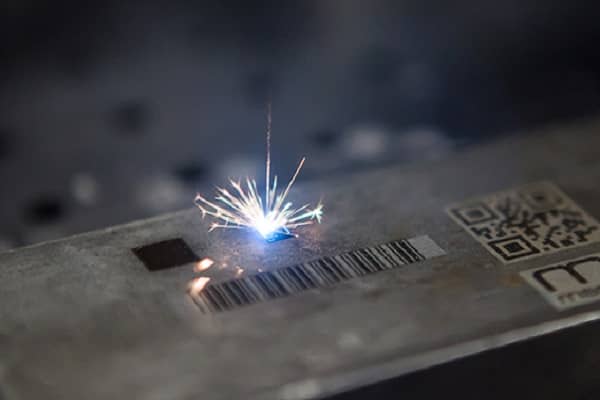

The basic principle behind laser marking is to deliver a concentrated beam of light to the surface to be marked. The light causes a chemical reaction in the surface, which results in a permanent change in the chemical makeup of the material. A beam of light is then applied to the area to be marked, which results in the formation of an image in the surface.

The most common types of laser marking applications are: Laser marking can be automated and processed at high speeds, while leaving permanent traceability marks on a range of materials, including steel, titanium, aluminum, copper, ceramic, plastic, glass, wood, paper, and cardboard. Parts and products can be marked with text (including serial numbers and part numbers).

The growth of machine readable data (Mrd) and its use in the manufacturing sector has been exponential in the past few years. It is estimated that by the end of 2015, there will be around 1.5 billion devices in the world that can read Mrd. As this technology becomes more commonplace, we will see a shift in the way products are packaged, tracked, and delivered.

What Is Engraving?

In the past, engraving was a costly, laborious process. However, advancements in technology have made engraving faster, cheaper, and easier.

Laser engraving can be used on a wide range of materials including wood, metal, glass, plastic and paper. The laser cuts through the material and leaves behind a permanent image that will last for decades, even if exposed to extreme conditions like rain, heat, cold, humidity and dust.

Barcodes are the most widely used data codes in the world. Barcodes are a way to uniquely identify a product, whether it is a book, a bottle of water, a loaf of bread or even an airline ticket. The reason why they are so popular is because they are easy to scan and they are not susceptible to damage.

Laser Etching vs. Laser Engraving

If you are looking to add some depth to a piece of jewelry, you could try etching. It is a great way to give your pieces an antique look.

You can use an etching tool to add more contrast to a piece. This is a very popular technique that can be used on jewelry, glass, pottery and more. It is great for highlighting details and creating depth in your work.

What Is Surface Marking?

If you’re looking for a quick and easy way to mark your artwork, you may want to consider surface marking. It’s a great way to add permanent markings to your artwork without cutting away the surface or using an acid-based technique.

Laser marking is the perfect solution for those looking to create a brand new look on products without having to go through a costly and time consuming rework process.

Types of Laser Machines

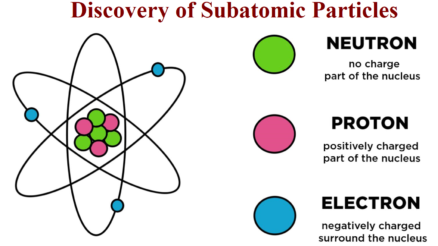

Laser markers are used to cut and engrave plastic, metal, glass, and wood. Solid-state lasers are lasers that use solid materials instead of gas. Some examples of solid-state lasers include Nd:YAG (yttrium-aluminum-garnet), Alexandrite (potassium titanyl phosphate) and DPSS (diode-pumped solid-state). Lasers that use gas are called gas lasers.

The two types of laser marking

Diamond is a very hard material, and the only way to mark it is with a laser. Diamond is used in jewelry, and if you think about it, jewelry is often stolen. So, when someone steals your diamond, the only way to prove that it was yours is to mark it with a laser, so that it can be traced back to you.

So the first type of laser marking is simply removing material by heating it up with a laser beam. The second type of laser marking is called engraving and involves cutting into the surface of the object.

This is similar to a normal laser printer, except it uses a different type of light to etch the image onto the paper. It is a process called “Laser Engraving.